Water Cooling Channels Decrease 3D Printed Mold Tool's Cycle Time by 50% - Fortify

Por un escritor de hombre misterioso

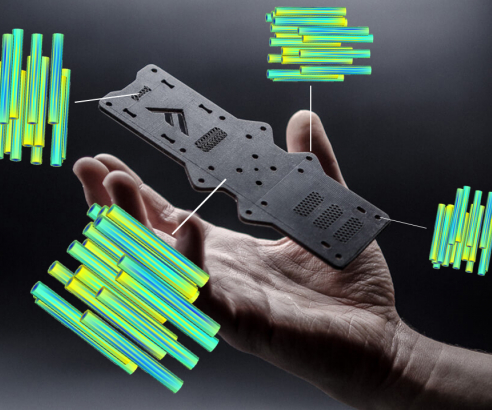

Fortify and PTC worked together to prove out if water cooling channels designed into the 3D printed mold tool could help reduce cycle time.

Reduce 33% Cycle Time through CAE Evaluation Method of Conformal Cooling System, Blog, Moldex3D

Review on 3D printing techniques for cutting tools with cooling channels - ScienceDirect

Review on 3D printing techniques for cutting tools with cooling channels - ScienceDirect

Processes, Free Full-Text

Benjamin MacDonald on LinkedIn: #additivemanufacturing #injectionmolding

Conformal cooling: How Additive Manufacturing benefits injection moulding

Development of green conformal cooling channels for rapid tooling

Magnetic 3D printing the next generation of tailored composites

Processes, Free Full-Text

Design and optimization of conformal cooling channels for injection molding: a review

3D printed tooling features conformal cooling channels - Make Parts Fast